Assignment 3: Reflection

Reflection On Fuel Tank Project

The entire Assignment 2 crafting progress can be found under the link over here.

BEIL0014 Digital Making -- Assignment 2 Project: The 1:1 Scale Fuel Tank

Review On Stage 1: 3D Model & Assemble

At the step when we import our 3d fuel tank

model into Autodesk Slicer to prepare our fuel tank template for laser cutting,

we all discussed at that time that we need to make more rigid and harder

surface of tank template to hammer and shape the metal on the template.

|

| Shape the metal piece on the tank tamplate |

The method we chose at that time is to

build the model using total 26 slices on both axis, which means 13 slices on

horizontal X and 13 slices on vertical Y. We thought total 26 slices for the

tank template is stable and solid enough, but we did not create the shell of

the tank. As a result, some template frames was snapped off when we hammer the

metal piece on it, which will be out of the shape and become inaccurate. After

all, we find out other groups all using masking tape to provide a smooth shell

to protect the template framework, which should be learned by our group.

Initial fuel tank template

Template after the project

Also, we used a total of 9 sheets of 3mm

plywood for making the tank template, the number of sheets can be seen as the

waste of materials and not environmental friendly.

Laser cutting the tank template

Material wastes

As we did not want the slices being too

difficult to slot together, we chose to ensure that the slot width is slightly

wider than 3mm. Also, we need the extra space for inconsistent material

thickness for putting glue between. So, we all agreed the slot width is set to

3.5mm. I found out some other groups did not consider this, as the result, they

required a lightweight hammer to force the sheets joining together, so it is

good for us to modify the width of the slot on the earlier stage in order to

assemble the pieces easier.

Choosing 3.5mm slot width

When we were making the 3d template model

in slicer, we did not leave of the gap on the back of the fuel tank, our group decided

to cut this gap off the metal piece at the end of the making process. The method

we did was cutting a paper template first from the fuel tank model and tape the

paper on the right position of the aluminium, then using the pencil to draw the

marking line and using tin snips to cut the shape off. But as this is at the

later steps when the aluminium piece is already hammered and curve at a good

shape, and the method using paper template for marking is something inaccurate,

it is quite hard to using tin snips to cut the straight line as we thought. The

border line of the gap shown on the final product is not satisfied by us, maybe

we leave the gap on the back of the model template on the earlier stage can

make the final product more accurate.

The border line of the back gap

Review On Stage 2: Metal Shaping

The piece I choose to make is the top piece

of the fuel tank, which is a large piece of the metal. The most significant

thing to consider is that it has a sharp curve on the two longitudinal sides

which can cover the left and right pieces under it, and a smooth curve along

the longitudinal axis. So, both curves on the perpendicular directions make the

top piece hard to shape, the tension and compression forces increased significantly

on the perpendicular directions when I hammered the metal piece.

Both curves on perpendicular axis

At the earlier stage, the most significant

problem I made is that I did not learn from the bowl making that drawing the

circular marking on the metal piece to guide me shape the curve. My method is only

using the paper template to draw the mark of boundary line on the aluminium. As

the result, I had to hammer the metal piece frequently between the fuel tank

template and the sphere stump or sand bag, it will waste lots of my time and

hard to shape the curve, especially comparing the bowl, the tank is much larger

and in a streamline shape.

Circular marking on the metal piece

The good technique I used at this step is when

cutting the aluminium, I left the extra space on the margin of pencil mark,

which will prevent the sheet shrink into smaller size after hammering it.

Also, I used 3 wood battens and 2 clamps to

make a simple bending tool on the table. Basically, my aluminium sheet

underneath the middle batten and bend the aluminium on the edge of the table to

make a good curve as my fuel tank template. The advantage of this bending tool

is that it won’t get the clear bending mark on the aluminium and will give me a

good curve of the aluminium on the longitudinal axis, also I don’t need much

effort to bend.

Using simple bending tool

After reviewing the process of hammering

the metal piece, I have been frustrated shaping both curve on perpendicular

axis of my top piece through the earlier process. As I strike a perfect

horizontal curve, the aluminium will become flat vertically and vise versa. It is

hard to find the balance of both perpendicular curves on the top part. Also, I

found it is difficult to make a good symmetrical aluminium for my top part,

because the sheet is too big to control the curve of the sheet, when striking

it will slightly tilt to one side and hard to adjust the shape.

But after the whole hammering process I find

out that the aluminium also has its own memory, if we did not hammer it to

enough extent, the curve of the aluminium sheet is not stable and will recover

to its original shape. This can be explained the problems I reviewed above when

hammering the curve of the metal piece. I did not hammer the sheet to enough extent,

the metal still has its own memory, and with the tension and compression

forces, the curve will recover quickly when I hammer on other places on the

sheet. Hence, as I spend more time on shaping the piece by hammering, the shape

become accurate and consistent to the shape of the template.

Hard to find the balance of both perpendicular curves

The most effective method I used through

the shaping process is cooperating with the hammer and English wheel. As I used

a lightweight hammer to tap softly, with continuous comparing with the

template. At the same time, keeping using the English Wheel a lot to smooth the

surface, which makes the model much smoother and shinier, and reduce the ugly hammer

marks.

Cooperating with the hammer and English Wheel

Also, we used a new tool which called the

bead roller for the both side parts of the fuel tank, tipping the contour line

of the top part on the side parts to make the top part edge perfectly covered

on the tipping line.

The use of bead roller

Another problem is that we did not polish the

fuel tank pieces this time, which leads our finished fuel tank do not look

shine enough and still can see some hammer mark on the surface.

Review On Stage 3: Teamwork

One of the greatest thing in our group is

that our members not only make our own part, we all cooperate with other

members and help them to shape their pieces. Almost in every photo that we took through the project, it always has one member help holding the metal piece on the tamplate while another hammering it, which I believe it is called turely teamwork.

As we all believe that even though

the fuel tank is built with different parts, but the fuel tank itself should be

seen as a whole, and each pieces of the tank should fit to each other. That is

why our group took much more time on building the tank pieces together and

every piece fits to each other, the whole fuel tank looks very smooth.

Teamwork

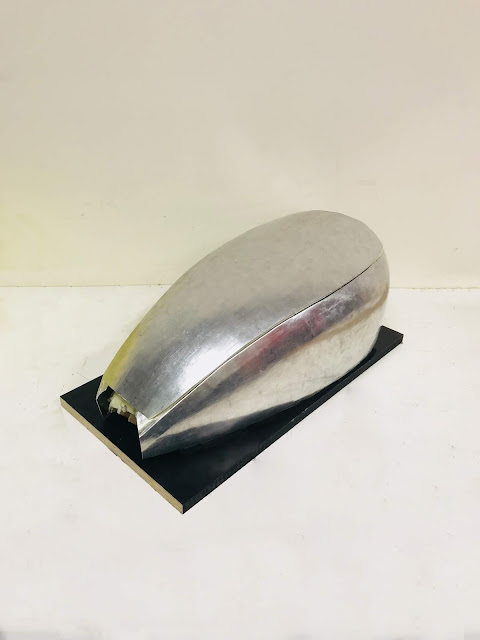

Final fuel tank

Comments

Post a Comment