Metal Tray

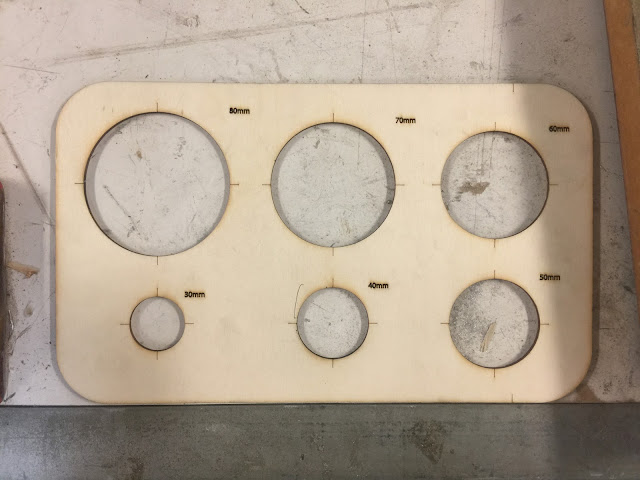

In week 4 we learned how to make the metal tray. Two people are in a small group, each person did the tray individually, then combine both trays together to see if they fits perfectly. Step 1: Dtermining which arc we should draw on the plank from the pre-prepared arc template. Usually when the arc is smaller, the tray is more difficult to make. I choosed the smallest arc, which is 30mm, to challenge myself if I can make it. Using the arc template to draw the arc on the four corners of the plank. Step 2: Using the sanding machine to grind off the perpendicular corners following the guiding arc lines we just drawn. The plank will be used as the template for striking the tray later. Step 3: Placing the plank on the top of the aluminum sheet to draw the shape. The space around the tray will be bended inward when striking later, so we need to leave the bended space on the aluminum sheet. The length of the outer bended part should be equal to the